In today’s electrical and electronics industry, efficiency, reliability, and precision are key. One of the critical components that ensure smooth electrical power transmission in industrial, commercial, and residential systems is the copper busbar. To manufacture these essential components dobladora de barras de cobre, industries rely on copper busbar machines, which have become indispensable for modern electrical engineering.

What is a Copper Busbar?

A copper busbar is a metallic strip or bar made of high-conductivity copper, used to distribute power efficiently from incoming feeders to outgoing circuits in electrical panels, switchgear, and substations. Copper busbars are preferred due to their excellent conductivity, thermal stability, and resistance to corrosion.

Role of Copper Busbar Machines

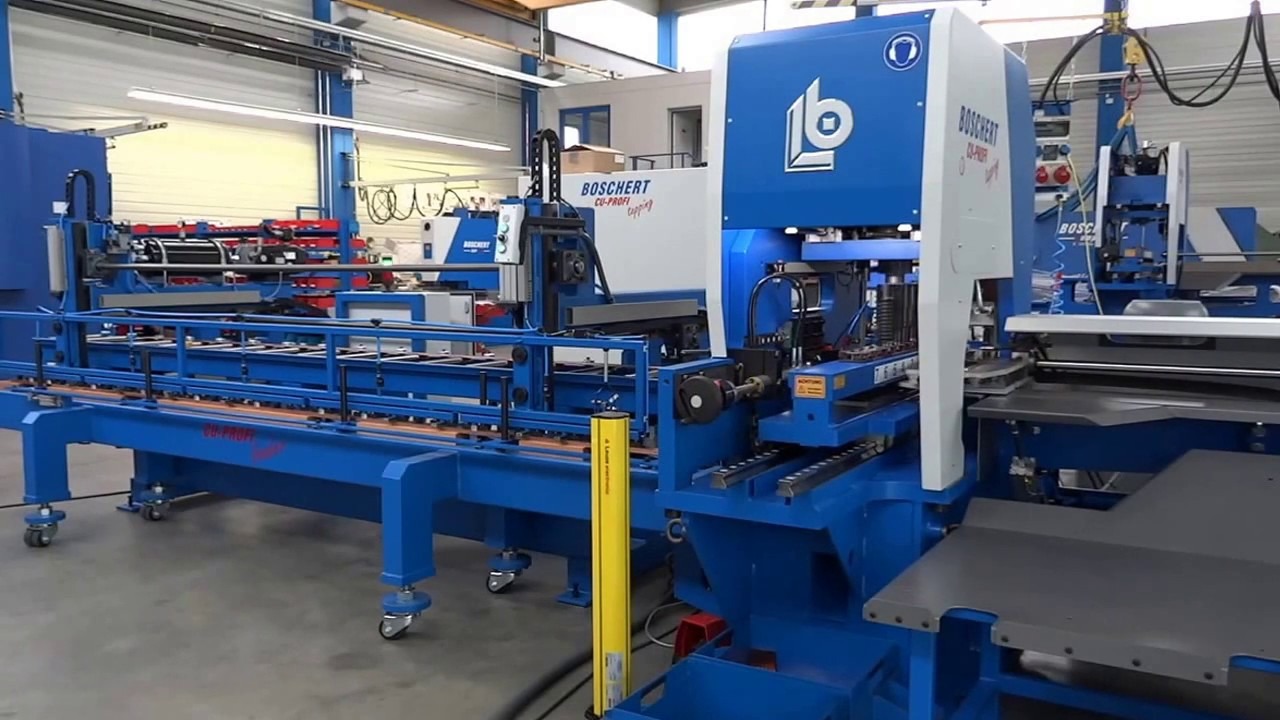

A copper busbar machine is a specialized industrial machine designed to cut, bend, and process copper bars into precise dimensions for electrical applications. These machines streamline production, reduce manual labor, and ensure consistent quality in the fabrication of busbars.

Key Functions:

-

Cutting: Copper busbar machines can accurately cut copper bars into specific lengths required for different applications. Precision cutting is essential to maintain proper electrical conductivity and fit within electrical panels.

-

Bending: Copper busbars often need to be bent into complex shapes to fit switchgear or distribution boards. Busbar machines can perform single or multiple-angle bends without damaging the material.

-

Punching: Many busbars require holes for bolting and connection to other electrical components. Modern machines integrate punching capabilities with high precision.

-

Shaping and Forming: Some machines are capable of forming copper strips into U, L, or Z shapes, ensuring that busbars meet design specifications while minimizing waste.

Types of Copper Busbar Machines

-

Manual Busbar Machines: These require operator intervention for cutting and bending. Suitable for small-scale production.

-

Semi-Automatic Machines: Combine manual operation with automated features like bending or punching.

-

Fully Automatic Busbar Machines: High-end machines capable of processing multiple busbars simultaneously, with programmable settings for cutting, bending, and punching. Ideal for mass production.

Advantages of Using Copper Busbar Machines

-

Precision: Accurate dimensions reduce electrical resistance and ensure safety.

-

Efficiency: Faster production than manual processing.

-

Consistency: Uniform product quality across large batches.

-

Reduced Waste: Optimized cutting and bending minimize copper wastage.

-

Labor Savings: Automation reduces reliance on skilled labor for repetitive tasks.

Applications of Copper Busbars

Copper busbars fabricated using these machines are widely used in:

-

Electrical switchgear and control panels

-

Substations and transformers

-

Renewable energy systems (solar and wind power)

-

Electric vehicles and charging stations

-

Industrial machinery and distribution boards

Conclusion

The copper busbar machine is a vital piece of equipment in modern electrical manufacturing. By automating cutting, bending, punching, and shaping processes, these machines improve production efficiency, ensure high-quality outputs, and enable electrical systems to operate safely and efficiently. As the demand for electrical power and renewable energy systems grows, the role of advanced busbar machines becomes increasingly critical in supporting reliable and sustainable electrical infrastructure.