A356 Aluminum Casting is a fascinating and intricate process that transforms a simple concept into a tangible creation. This versatile manufacturing technique has been employed for centuries, evolving with technology and innovation to produce an array of products across industries. In this blog, we will embark on a journey that takes us from the initial concept of aluminum casting to the final creation of intricate components and parts.

The Concept: What is Aluminum Casting?

At its core, aluminum casting is the process of creating objects by pouring molten aluminum into a mold and allowing it to cool and solidify. The result is a three-dimensional replica of the mold, with intricate details and complex shapes accurately reproduced. This process is used to create a wide range of products, from automotive parts and aerospace components to kitchenware and artistic sculptures.

The Journey Begins: Design and Prototyping

The journey of aluminum casting begins with a concept or design idea. Whether it’s a new car engine component, a decorative lamp base, or any other aluminum product, the first step is to create a detailed design. This design phase involves CAD (Computer-Aided Design) software, where engineers and designers create 3D models of the intended product.

Once the design is finalized, a prototype is often created using various methods, such as 3D printing or CNC machining. Prototyping allows for testing and refining the design, ensuring that it meets the desired specifications and functionality.

Creating the Mold: Tooling and Patternmaking

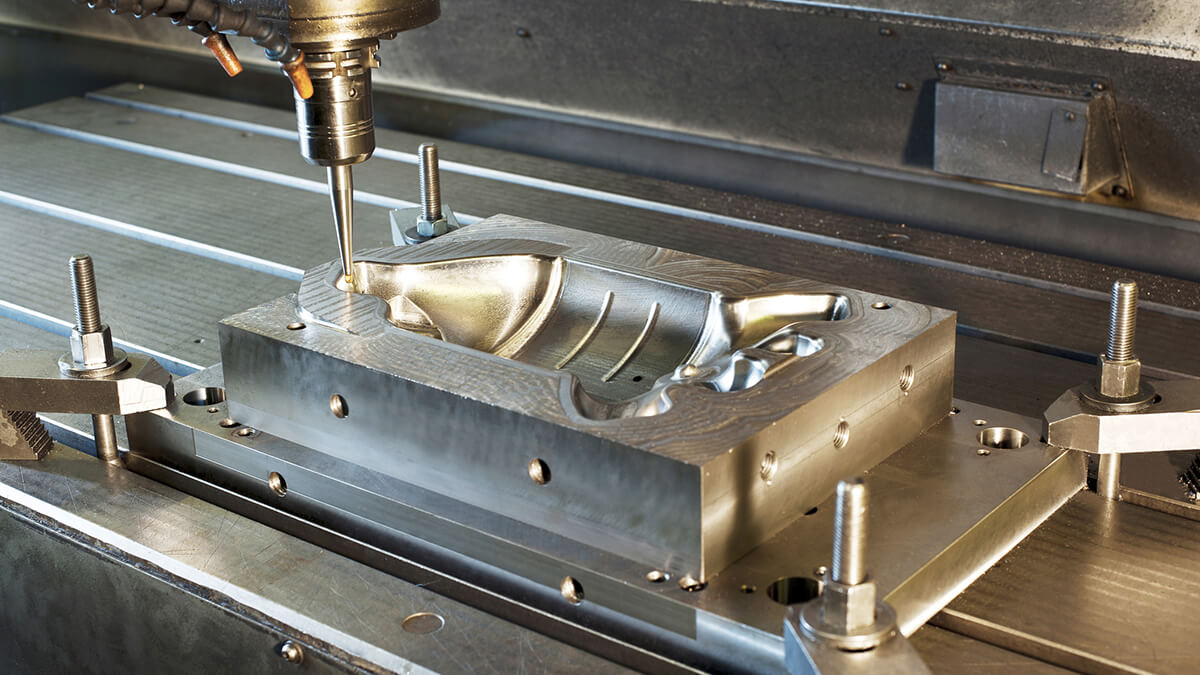

With the prototype approved, the next step is to create the molds or patterns that will be used in the casting process. These molds are typically made from materials like wood, metal, or resin, depending on the complexity of the product and the casting method chosen.

For intricate or one-of-a-kind components, the mold is typically carved or machined from a solid block of material. In mass production, reusable molds made from steel or other durable materials are often used. These molds are carefully crafted to ensure that they capture all the details of the prototype accurately.

The Casting Process: Melting and Pouring

Once the mold or pattern is ready, the actual casting process begins. This involves melting aluminum alloy, which is a combination of aluminum and other metals like copper, zinc, or magnesium, in a furnace. The specific alloy composition is chosen based on the desired properties of the final product, such as strength, durability, or corrosion resistance.

The molten aluminum is carefully poured into the prepared mold, filling it completely and taking the shape of the prototype. This process requires precision and expertise to avoid defects like air bubbles or incomplete filling. As the aluminum cools and solidifies, it takes on the shape and details of the mold.

Finishing Touches: Removal and Cleanup

After the aluminum has fully cooled and solidified, the mold is opened, revealing the newly cast product. However, the freshly cast component is not yet ready for use. It undergoes a series of finishing steps, including trimming excess material, sanding or machining to achieve the desired surface finish, and sometimes heat treatment for improved mechanical properties.

Quality Control: Inspection and Testing

Quality control is a critical part of the aluminum casting process. Each component is inspected for defects and imperfections, such as cracks, porosity, or dimensional inaccuracies. Non-destructive testing methods like X-ray or ultrasonic inspection may be employed to ensure the integrity of the cast product.

The Final Creation: Application and Use

Once the cast aluminum component has passed all quality checks, it is ready for its intended application. Whether it’s a crucial automotive part, a decorative architectural element, or any other product, aluminum casting plays a vital role in modern manufacturing.

Conclusion

The journey from the initial concept to the final creation of aluminum cast products is a testament to human ingenuity, precision engineering, and the marvels of modern manufacturing. Aluminum casting has enabled the creation of intricate and complex components that are vital in various industries, and it continues to evolve with advancements in materials and technology. This age-old process showcases the beauty of transforming an idea into a tangible reality, illustrating the endless possibilities of aluminum casting in the modern world.